SMM: not long ago, foreign media reported that Kia will launch an 800V battery charging system, and the model with this system is a cross-border car that Kia announced in January this year, which will be launched in 2021 and born from Kia's first pure electric platform. According to Kia, the model will have a range of about 300 miles and can be recharged in up to 15 minutes under an 800V battery charging system.

So far, the typical example of the battery architecture of 800V electric vehicles is Porsche's Taycan, which is also the only mass-produced model with 800V system. However, the low-end version of the car starts at 888000 yuan in China, while the high-end version starts at 1.798 million yuan, which is far beyond the acceptance of the vast majority of consumers.

High-voltage charging platform is essentially high-power charging. For high-premium models such as Porsche Taycan, the high added value brought by high-cost configuration such as 800V charging system can complement each other for brands.

But for most ordinary consumers, is high-voltage and high-power charging really necessary?

High-power charging has become a rigid demand.

In recent years, the average mileage improvement speed of electric vehicles in China can be said to be running forward. A few years ago, models running around 150km ran all over the street. By the 2018 Beijing Auto Show, the driving range of mainstream models has been upgraded to 400km. By 2020, 500km battery life has become the entry value for most consumers to consider battery life when buying electric cars, and the models with the highest range have exceeded the 700km.

For long-range cars, the battery charge is basically between 60~100kwh, in the case of the same charging efficiency, charging time is bound to become longer, for these consumers, mileage anxiety is turning into charging anxiety.

At the same time, as the main consumer group of electric vehicles, most consumers in mega-cities such as Beijing, Shanghai, Guangzhou and Shenzhen are facing the problem of shortage of parking spaces, which means that for these consumers, the demand for public charging is rigid, and some even use it as the main way of charging.

At the 2020 Teda Forum on Sept. 5, Li Bin, CEO of Xilai, said that it is easier to turn on electricity than to refuel, because 70% of users can recharge at home.

Regardless of where the 70 per cent of the data comes from and whether it is accurate or not, according to the Ministry of Public Security, as of June 2020, the number of new energy vehicles in China reached 4.17 million, even if calculated with the figure of 70 per cent. about 1.25 million of consumers are unable to recharge at home, which is not a negligible figure compared with the fact that there is almost no "fuel anxiety" among fuel truck users. At the same time, in the highway use scene, with the further popularity of electric vehicles, there is bound to be a large number of centralized charging demand in the National Day, Spring Festival and other time periods, how to improve charging efficiency to avoid congestion has become the key.

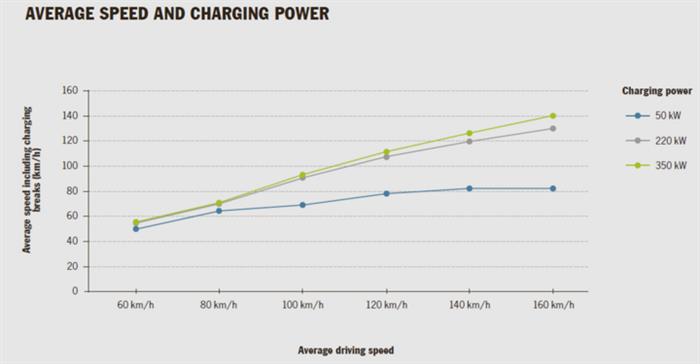

Figure 2: average speed and charging power, screenshot from "New Possibilities with 800-Volt Charging"

As can be seen from the above picture, if the charging power is only 50kW during a long distance, even if the average speed of the whole driving is as high as 160km / h, after adding the charging time, the average speed of the whole driving process is only about 80km/h, and the efficiency is very low. In the case of high-power charging of 350kW, the average speed can be increased to about 140km/h after taking into account the charging time.

Figure 3: quick charging example, screenshot from "New Possibilities with 800-Volt Charging"

Figure 3 shows us the improvement of the car experience brought about by high-power charging in terms of time.

A section of the 720km journey, a fuel vehicle driving at a higher speed, experienced a refueling, the whole journey takes about 5.5 hours; For an electric car that needs to be recharged twice, the whole journey takes 8 hours if the charging efficiency is 50 kw. if it is the charging efficiency of 350kW, the time is reduced to 6 hours, and there is only a 10% time gap between the electric car and the fuel car. if this is a high-endurance model that only needs one charge midway, the time gap will be further narrowed.

Therefore, in order to alleviate the charging anxiety of most users, improve the charging experience, and meet the fast charging needs of specific scenarios, the development of high-power charging has become a rigid demand.

Leading companies have laid out

In the face of such demand, under the leadership of Musk, who believes in the "first principle", Tesla began to layout his own super-charging pile network a long time ago. In March last year, Tesla V3 super charging piles opened to users in a parking lot in San Francisco, USA. This is an overcharging method that uses a new architecture and can support peak charging power up to 250kW. Some Model 3 models can be recharged for 15 minutes with a maximum battery life of about 250km.

As a new car-building force deeply influenced by Tesla, it has also invested enough attention in the charging plate. Xiaopeng built its first super charging station in Guangzhou in 2018, but at that time, due to various conditions, the charging pile could theoretically achieve the charging power of 300kW, but the actual charging power was only 90kW.

In June this year, Dr. Liu Minghui, vice president of Xiaopeng Automobile, said in an exclusive interview with the media that the maximum charging power of Xiaopeng's self-built charging pile can reach 180kW, and at the same time, it is also developing fast charging technology to adapt to the future, probably above 300kW.

On the other hand, at last year's Shanghai Auto Show, it unveiled its super charging pile NIO Power Charger, which has the output power of 105kW, which well makes up for its shortcomings in efficient and low-cost energy replenishment. at the same time, this service is not limited to Weilai car owners, so it also increases the channel of revenue.

Although the output power of the charging pile is not increased but decreased compared with the general 120kW fast charging pile, when the charge state, State of Charge) of the battery is less than 60%, it can run almost 90 kW, and the charging current is also close to the 250A peak of the upper limit of the national standard, which can increase the charging time by about 10 minutes compared with the ordinary fast charging pile.

Traditional car companies such as BAIC New Energy have also made technical reserves in high-power charging.

According to the first Electric Network, as early as the beginning of 2018, BAIC New Energy established a high-voltage and high-power DC charging technology development project, which aims to provide technology and resource reserves for high-voltage systems with high voltage and high current. Once the market demand breaks out on a large scale, the existing high voltage system of the target model can be quickly replaced and the fast charging ability can be realized through the modification.

It is reported that the project is divided into two phases, and the first phase has been completed at the end of 2018, realizing the goal tasks such as the development of charging function and the development of components for high-voltage platform, and the charging capability verification of maximum charging current 266A (3.2C) and maximum charging power 175kW has been realized on the charging pile of the national network.

In the second stage, the goal of BAIC New Energy is to achieve the fast charging capacity of maximum charging current 412A-516A and maximum charging power 265-340kW. In both stages, the system voltage platform is close to 600V, and it is understood that the second phase of the project will be checked and accepted next month.

The dilemma still exists.

However, although the market has rigid demand, and related enterprises are also carrying out corresponding research and development, high-power charging is still faced with all kinds of difficulties in the process of popularization.

The first to bear the brunt is the communication protocol.

When Weilai launched the 105kw super charging station, some consumers wondered why the maximum output power of 105kW was limited to 105kW when public charging piles could basically achieve the maximum output power of 105kW at that time.

The reason is that as mentioned above, the national standard stipulates that the maximum DC charging output current can not exceed 250A, while the charging voltage of most electric vehicles can only reach 410V, which means that no matter how high the peak charging power of the charging pile is, in the end, most electric vehicles can only get a peak charging power not higher than that of 102.5kW (410V*250A).

The reason why Tesla can achieve high-power charging is that his own standard is adopted in the communication protocol with the vehicle, which is not restricted by the national standard. In the above-mentioned BAIC new energy project, the second phase of the development plan includes the supplement and improvement of the communication protocol.

In the face of the development of an 800V high voltage system similar to the Porsche Taycan, the power battery, an important core component of the electric vehicle, has become the key.

The difficulties mainly come from two aspects:

First, the fast charging bottleneck of the chemical system.

A senior engineer of a power battery company introduced to the first Electric Network, "the conventional cell chemical system design is difficult to achieve 15-20 minutes of super fast charge." In order to realize super fast charging, it is necessary to optimize the micro layer of the main materials of the battery (including positive electrode, electrolyte, negative electrode and separator). In addition to the optimization of the material level, it is also necessary to optimize the macroscopic structural design of the cell, module and battery package-level Synchronize (including the overcurrent capacity of the structure, the layout of high and low voltage wiring harness, etc.). This is bound to bring higher design difficulties, but also lead to an increase in the overall cost to a certain extent. "

Second, the battery heating problem at high charge / Discharge power.

The engineer said, "the cell itself has a certain internal resistance, and the current is larger at high charge / Discharge power (that is, high rate fast charge and high current repeated pulse discharge), so not only the temperature of the structural parts of the battery package will rise rapidly. The temperature of the cell will also rise significantly. If the temperature of the cell remains high during the charge and discharge period, it will damage the performance of the cell in all aspects. This requires that the water cooling system of the whole battery pack must be designed reasonably, and the water cooling system needs to provide sufficient cooling power to reduce the temperature rise during battery charge and discharge and ensure that the cell works in a comfortable environment. "

It is understood that at present, domestic power battery head enterprises, including Ningde era, have relatively good mature solutions. For 800V high voltage system, it can support fast charging for 15 minutes and ensure that the battery performance will not deteriorate significantly during use. Faster charging speed is under development in Synchronize.

At the level of charging infrastructure, it is understood that the difficulties faced at present are not great.

"as a charging pile enterprise, it does not seem to be too difficult at present, mainly on high-voltage connectors and high-voltage modules, China's supply chain is relatively strong, all of which have been solved." "High-voltage charging technology is mainly reflected in the unique design of the battery pack, while all the new private charging piles in China are 200V-1000V wide-voltage charging piles, which can well meet the charging needs of this kind of electric vehicles," Ding Rui, CEO of Zhicong Technology, told the first Electric Network.

High-power charging is not a substitute for the original charging method.

Convenient charging is one of the core demands of electric vehicle end-users, and it is also the key to restrict the further rapid development of electric vehicle industry.

According to some market research data, on the premise of a sound charging foundation in the future, from the user's point of view, the charging time needs to be less than 10 minutes, so that the charging experience of electric vehicles will have a chance to achieve a level similar to that of traditional fuel vehicles.

"charging to 90% in 15 minutes is a very good experience. When we go to the gas station to refuel, we also buy water, issue tickets, and so on. The average time is about 10 minutes." Ding Rui expressed a similar view.

However, no matter which kind of scene is different from the fuel vehicle in the gas station, for electric vehicles, different use scenarios have different relatively optimized solutions, and high-power charging is not a simple alternative to the existing energy supplement. It's an effective supplement.

If high-power charging stations are built on a large scale, the problem of overload is easy to occur in the period of tight power supply, resulting in line overheating, tripping and so on, resulting in a large number of loads being removed. Therefore, high-power charging stations need to be laid out in places of real demand, such as highway service area, rental, online car-hailing parking stations, etc., which is more conducive to the rational layout of Electroweb and enhance the peak-shaving capacity of Electroweb system. At the same time, energy storage devices can be integrated to reduce the short-term impact on Electroweb.

Generally speaking, the popularity of regular charging stations requires the cooperation of vehicle factories, power battery enterprises, charging facilities, Electroweb and other aspects in order to finally bring a cost-acceptable solution to the market. This solution will be a key step for electric cars to be truly accepted by consumers.

"Click to understand and sign up: 2020 China Automotive New Materials Application Summit Forum

Scan the QR code above to view the business cards of the participating companies and sign up online

Scan the code and apply to join the SMM Automotive Industry Exchange Group.