Bauxite residue, commonly known as red mud, is a highly alkaline by-product generated during the Bayer process of alumina extraction from bauxite ore. With global alumina production steadily increasing to meet the demands of various industries, the volume of red mud produced has surged correspondingly, posing significant environmental and management challenges. The red colour is due to the presence of iron oxides (along with other oxides).

The multifaceted nature of red mud demands an immediate and thorough understanding to mitigate its adverse effects and harness its potential benefits. Red mud contains unreacted minerals, metal oxides, and caustic soda, making it toxic if not managed properly. Its disposal has traditionally involved storage in large containment areas, which poses risks such as leakage, dam failure, and contamination of soil and water resources.

Despite these challenges, red mud also presents exciting opportunities for resource recovery and utilisation in various applications. Advances in research have explored its use in construction materials, soil remediation, and even as a source of valuable metals.

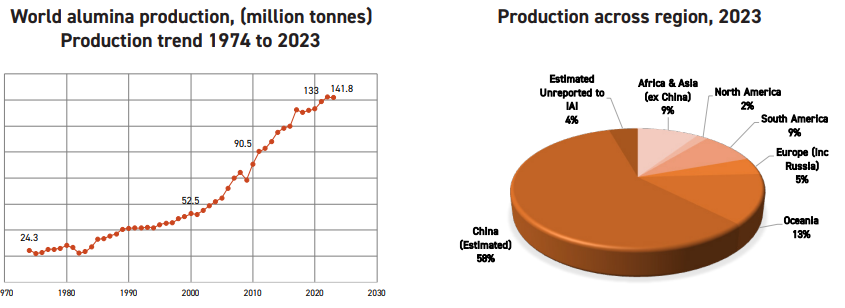

Alumina production worldwide stood at around 141.8 million tonnes in 2023. The key alumina-producing countries, including China, Australia, Brazil, and India, account for about 80-82 per cent of the global production.

Source: IAI, various publications

Source: IAI, various publications

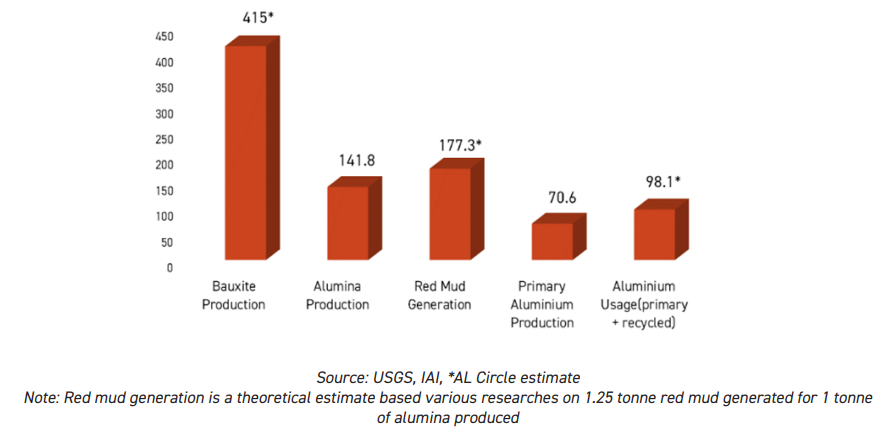

On average, for every tonne of alumina produced, around 1.25 tonnes* of red mud is generated. It is estimated that in 2023, alumina refineries across the world generated around 177.25 million tonnes of red mud. Concerns over red mud disposal and storage have gained widespread attention since 2010 when the tailing dam attached to the Ajka alumina plant in Hungary failed. This caused flooding of several towns, resulting in casualties as well as injuries to scores of people. While recycling aluminium may ease some pressure, the demand for primary metal will continue to grow annually in the foreseeable future. This implies a growing demand for alumina, indicating increased red mud generation. There are challenges facing the aluminium industry worldwide due to legacy and active tailing dams storing red mud.

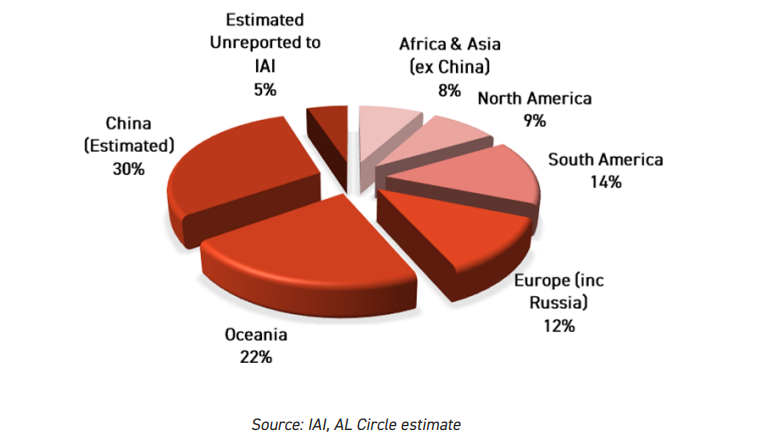

Red mud generation by region (1974-2023)

Red mud generation

The quantity of red mud generated per tonne of alumina produced depends on the type of bauxite used. This may range from as low as 0.8 tonnes for various high-quality bauxite to 2.5 tonnes for very low-quality bauxite produced. However, according to various sources, the typical quantity of red mud generated falls in the region of 1 to 1.5 tonnes per tonne of alumina produced.

Red mud generation & various aluminium industry parameters, 2023 (million tonnes)

It is estimated that across the world, 177.3 million tonnes of red mud was generated in 2023 against an alumina production of 141.8 million tonnes. Only 2-5 per cent of the total red mud generated annually is being utilised as a saleable by-product since most of it is sent to the tailing dams. Worldwide, it is estimated that more than 4 billion tonnes of red mud had been accumulated in various legacy and active tailing dams.

It is estimated that across the world, 177.3 million tonnes of red mud was generated in 2023 against an alumina production of 141.8 million tonnes. Only 2-5 per cent of the total red mud generated annually is being utilised as a saleable by-product since most of it is sent to the tailing dams. Worldwide, it is estimated that more than 4 billion tonnes of red mud had been accumulated in various legacy and active tailing dams.

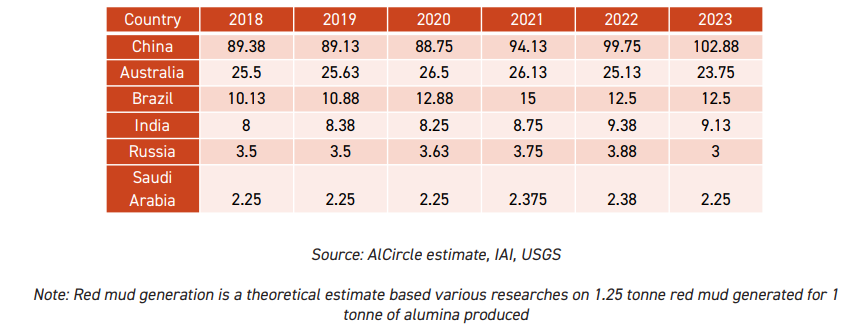

Red mud generation trend across major countries, 2018 to 2023 (in million tonnes)

AL Circle’s industry-focused report, “A Comprehensive Analysis of Bauxite Residue - Red Mud,” delves into the complexities associated with red mud, encompassing its chemical composition, environmental impact, current disposal practices, and potential for reuse. Secure your copy now!

The report thoroughly examines the composition, environmental impact, and innovative management strategies for bauxite, commonly known as red mud. This report is essential for industry professionals, policymakers and environmentalists looking to stay informed about sustainable practices and advancements in bauxite residue management.

Utilisation of red mud

The main constituents of red mud are a mixture of unreacted metallic oxides. In addition to iron, the associated liquor includes trace levels of other metallic oxides such as nickel, potassium, thorium, uranium, vanadium, zinc, and rare earth elements. Multiple research works related to red mud valorisation have either gone into or are in progress across the world. Companies and research organisations are working to find ways of commercial utilisation by extracting other minerals and towards reducing the toxicity of red mud and improving processing and storage methods in managing red mud. Discover in-depth insights into red mud utilisation for a sustainable future—get your copy today!

Conclusion

The demand for aluminium is expected to rise significantly in the coming years, driven by the increasing need for lightweight materials across various applications. Consequently, the demand for alumina will also grow. Effective red mud handling and valorisation methods have become more prominent within the industry supply chain at this critical juncture. Aluminium companies and research organisations are making concerted efforts to create value from red mud and mitigate its negative environmental impacts.

*Source: CSIR–NIScPR, ScienceDirect & AL Circle research

Image credit: ResearchGate (Red mud of the second mud storage of the Mykolaiv Alumina Plant)

Source: https://www.alcircle.com/news/red-mud-generation-trend-across-major-countries-2018-to-2023-112752

![Secondary Aluminum Alloy Enterprises Steadily Resume Operations After Chinese New Year [SMM Analysis]](https://imgqn.smm.cn/production/admin/votes/imageskkgTu20240508153005.png)

![Bullish sentiment strong aluminum ingot quotes firm [SMM Spot Aluminum Noon Review]](https://imgqn.smm.cn/usercenter/jWDCu20251217171653.jpg)

![Supply and demand gradually recover ADC12 prices mainly hold up well [SMM Cast Aluminum Alloy Morning Comment]](https://imgqn.smm.cn/usercenter/tXCfs20251217171653.jpg)