Recently, affected by the epidemic in Shanghai, Jiangsu, Jilin and other places, China's automobile industry has once again fallen into a state of wavering.

Among them, Shanghai is not only the core of the national automobile industry, but also the hardest-hit area of this epidemic. The development trend of the local epidemic affects the heart of the whole automobile industry. In order to gain a more in-depth understanding of the industrial development under the epidemic, Gesco launched a related topic research and received a total of 1779 valid survey results.

Among these participating users, more than 30% come from spare parts enterprises, 20% from whole vehicle enterprises, another 13%, and 11% users are raw material suppliers and technology providers, car dealers and logistics carriers account for about 10%. It is worth mentioning that more than half (55%) of the participating users are located in key epidemic areas, which provides a basis for the sample data of this survey to more truly reflect the current situation of the automobile industry under the epidemic.

Nearly 70% of enterprises are deeply affected by the epidemic, and logistics stagnation is the first to bear the brunt.

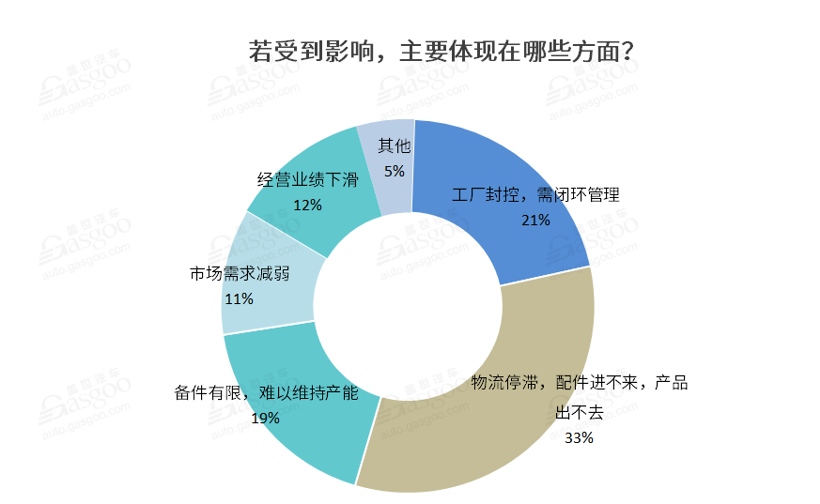

In the survey results, nearly 40% of people said that the epidemic has a great impact on the company's operations, accounting for 30% of the people think that the impact is greater. These effects are mainly reflected in two aspects: "logistics stagnation" and "factory closure".

In the face of the highly contagious new round of Omicron epidemic, in the early morning of March 28, Shanghai urgently adjusted its prevention and control strategies, from "gridding" management to "river control" and from "stubble control" to "global static management".

Also from March 28, high-speed exits in Jiangsu, Zhejiang, and Anhui provinces upgraded vehicle control measures in Shanghai. Tongling, Zhuji, Zhenjiang, Danyang and other places were directly advised to return. Xianju directly quarantined card collection drivers from Shanghai after getting off the highway.

The escalation of epidemic prevention and control almost made Shanghai, an international metropolis, press the "pause button", and the ensuing logistics stagnation began to affect various industries. It is understood that since March 28, in addition to epidemic prevention and daily necessities in Shanghai, a lot of production logistics have come to a standstill. For the automobile industry with long industrial chain and high correlation, the most direct result is that the raw materials and parts shipped from other places to Shanghai cannot be imported, and the products that need to be sent from Shanghai to other places can not be sent out. Even if a small number of logistics are operational, the time cost is much higher than before.

According to employees of an enterprise, due to the closure policy between different cities, it can only pull the product from the supplier warehouse to a point, unload the goods manually, and then transfer to another car at the highway intersection. so many transfers can be pulled into the factory in Shanghai.

However, a person from a foreign parts supplier said that before Shanghai was closed, the company's parts were on the highway, and when they arrived at the toll station, the other side saw that the vehicles were not released from Shanghai, and eventually the downstream car companies could only call forklifts to unload and transfer to the city, and the transportation cost was higher than the parts.

Spare parts can not get in and products can not get out, which is a common dilemma faced by automobile enterprises under the epidemic in Shanghai. Although 19% of the participants said that the enterprise has spare parts production, it is also difficult to maintain production capacity. A relevant staff member of a head wiring harness company told Galaxy that relying on inventory to prepare materials, all the lines of the company were basically making steady progress, but only maintained about 80% of the production capacity before the epidemic, and the preparation situation was already tight. Should only last a few more weeks.

With the escalation of epidemic prevention and control, in addition to the stagnation of logistics, the second biggest challenge faced by automobile companies in Shanghai is "factory closure and closed-loop management."

It is understood that as early as March 14, SAIC-Volkswagen's factory in Anting, Jiading, Shanghai, was notified to require the factory to carry out closed-loop isolation and control for 48 hours, but facts have proved that it is far more than 48 hours. As the epidemic enters the community, epidemic prevention and control measures continue to upgrade, and the closed-loop time has been extended again and again. SAIC GM's plant in Jinqiao, Pudong, also slowed production because of the epidemic.

Tesla's Shanghai factory also suspended production for two days in mid-March because of epidemic prevention, and then was forced to stop production again on March 28 after the implementation of the policy of "rowing the river and governing the river." originally planned to stop production for four days, but so far, its Shanghai factory employees are still at home, and when to return to work is still "inconclusive." When the first-quarter sales were released, Musk tweeted that "this is an extremely difficult period due to supply chain disruptions and outbreaks", but the suspension of production in April will make the second quarter more difficult.

In theory, in the case of adequate logistics supply, "closed-loop management" is effective, but the automobile industry is "pull one trigger and affect the whole body". For whole vehicle enterprises, there is no way to produce vehicles without a single spare part. As a result, after the upstream parts suppliers' production pace has been disrupted, downstream car companies have to slow down the pace of production and even be forced to stop production.

On April 9, Weilai officially announced the suspension of production. Since March, the company's supply chain partners in Jilin, Shanghai, Jiangsu and other places have stopped production one after another and have not recovered because of the epidemic, Weilai said. Affected by this, the production of the whole vehicle of Weilai has been suspended.

According to the news on April 14, the supply chain of Lulai has recovered slightly, and the production base of Hefei is gradually resuming production. However, Weilai also pointed out that its follow-up production plan also depends on the recovery of the supply chain. Considering the current epidemic situation, this means that there are still great uncertainties in the operation of its factories in the future.

Stay in the factory and adjust the production line flexibly, and each enterprise shows its ability to guarantee supply.

In fact, in order to deal with the impact of the epidemic, many enterprises are actively taking measures, among which "encouraging and arranging employees to work in the factory in a timely manner" has become the first choice for manufacturing enterprises to guarantee supply.

Take SAIC-Volkswagen as an example, Shanghai as its stronghold bears most of the production capacity. Public data show that SAIC-Volkswagen has 6 major production bases and 9 complete vehicle factories. Among them, the Shanghai base has a total of one factory, two factories, three factories and new energy vehicle factories, four factories are located in Anting Town, Jiading District. Among them, the new energy car plant was completed and put into production in 2020, with an annual production capacity of about 300000 vehicles; the other three plants have an annual production capacity of more than 820000 vehicles. This means that the Shanghai Anting base alone bears the production capacity of SAIC-Volkswagen more than 1.12 million vehicles.

As a result, SAIC-Volkswagen began consulting employees when it received a 48-hour closed-loop control notice on March 14, encouraging "closed-loop production" at the factory and preparing supplies such as camp beds, tents and yoga mats for resident employees. However, most of the employees are isolated at home, and the proportion of employees who can stick to work in the factory is small, so although the production line remains in operation, the pace of production has slowed sharply due to a shortage of manpower.

In addition, "flexibly adjust the existing production line, while relocating capacity to factories in non-epidemic areas" and "cooperation and alliance development together" have become spare plans for car companies.

On April 15, in view of the impact of the epidemic in Shanghai and other places on the automobile industry chain, the relevant person in charge of SAIC GM Wuling said: "at present, the company produces flexibly through the flexible adjustment of various bases, production lines, and product varieties, in order to minimize the negative impact of the epidemic."

GM headquarters also said the supply chain was implementing a global "contingency plan" to mitigate the impact of the restrictions. According to industry speculation, the so-called "contingency plan" may be to start the alternative supply of the AB plant.

A relevant person in charge of Ford Motor said that in the face of the severe external situation, the company is working with partners and suppliers to actively respond. "at present, our main production bases in Chongqing, Nanchang and Hangzhou have not stopped production. According to local epidemic prevention measures, we have formulated a sound plan to ensure the production of best-selling models."

In terms of parts and components enterprises, a local intelligent driving solution provider revealed that their company's inventory can only maintain production for less than three months, so the company is doing some pre-planning and mitigation as much as possible through the deployment of resources in different places, the cooperation of upstream and downstream industrial chain partners and shareholders.

Another Zhejiang supplier admitted in an interview with Galaxy that their company's supply of raw materials is expected to last only until the end of April and early May. At present, the company has also tried to find alternative suppliers around Shanghai, where their suppliers were previously based.

In order to prevent more car companies from shutting down work and production, the relevant ministries and commissions actively stepped in to guarantee the supply.

However, it should be pointed out that the long industrial chain and wide influence of an automobile made up of more than 30,000 parts can be seen, especially for downstream automobile companies, whether it is "closed-loop production" or "flexible adjustment." once the supply of upstream key parts is blocked, it is also impossible to make bricks without rice.

As Xiaopeng founder he Xiaopeng said on Weibo on the evening of April 14, if supply chain companies in and around Shanghai cannot find a way to dynamically resume work and production, all vehicle factories in China may stop production in May.

Subsequently, Yu Chengdong, Huawei's consumer business CEO and smart car BU CEO, also posted on Wechat moments, "if Shanghai cannot resume work and production, after May, all science and technology and industrial industries involved in Shanghai's supply chain will stop production completely, especially in the automobile industry, which will cause great economic losses and costs."

Therefore, in the increasingly difficult epidemic prevention and control war, in order to ensure the smooth supply chain of the automobile industry chain, seeking policy support has become the last bargaining chip of automobile enterprises. The good news is that judging from the trends in the past two days, the Ministry of Industry and Information Technology and the Shanghai Economic and Information Commission have all stepped in.

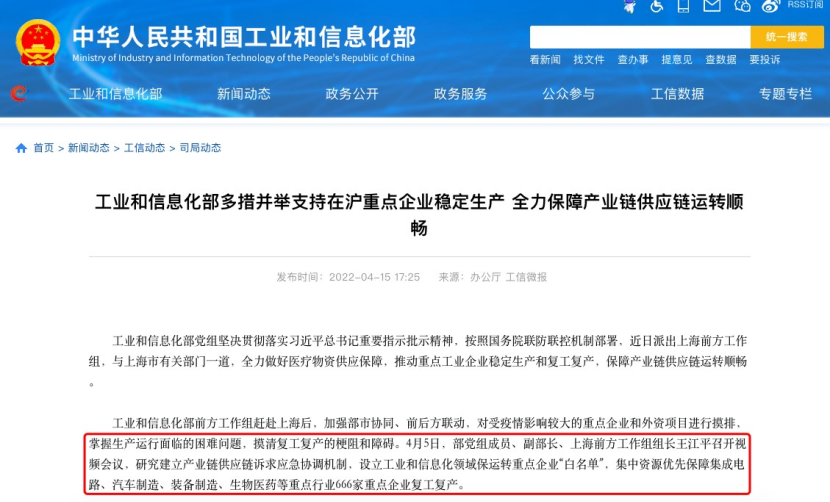

Source: website of the Ministry of Industry and Information Technology

On April 5, the Ministry of Industry and Information Technology studied the establishment of an emergency coordination mechanism for the demand of the industrial chain supply chain, and set up a "whitelist" of key enterprises in the field of industry and information technology to ensure the resumption of work and production of 666 key enterprises in key industries, including automobile manufacturing (11% of the country's output).

In order to further ensure the smooth flow of the automobile industry chain supply chain, on April 11, the China Automobile Association officially launched the "Automobile Industry chain supply chain unimpeded Coordination platform" to help automobile industry chain supply chain enterprises feedback and solve practical problems in a timely manner.

Recently, the Ministry of Industry and Information Technology dispatched a Shanghai front working group to work with relevant departments in Shanghai to strengthen coordination between ministries and cities and linkage between the front and rear, to sort out key enterprises and foreign-funded projects that have been greatly affected by the epidemic, to grasp the difficulties in production and operation, and to find out the obstacles and obstacles to resuming work and production.

After a series of actions, on the evening of April 16, the Shanghai Economic and Information Commission issued the guidelines on epidemic Prevention and Control of the resumption of work and production in Shanghai Industrial Enterprises (first Edition). The guidelines are clear: the governments of all districts, streets, towns, and parks should actively support enterprises to resume work and production, guide enterprises to "one enterprise, one policy", earnestly do a good job in epidemic prevention and control, set up nucleic acid testing sites and provide testing services, and dispose of medical waste in a timely manner. and provide underpinning services for the support of epidemic prevention materials and daily necessities.

On the afternoon of April 15, an internal document issued by Wang Xiaoqiu, vice president of SAIC, showed that SAIC was trying to promote the resumption of work and production. SAIC plans to give feedback on the return to work on April 17 and launch a stress test on April 18, according to the document. At the same time, the document said that SAIC will uniformly report to its subordinate enterprises the "whitelist" of enterprises that apply for early start-up of resuming work and production, and the approved list will be put on record in various districts, streets and communities. If it can be made, SAIC is undoubtedly an effective way to reduce losses, and other enterprises can also actively learn from it.

Half of the participants thought that the epidemic had a great impact on the car market, and the annual growth was not optimistic.

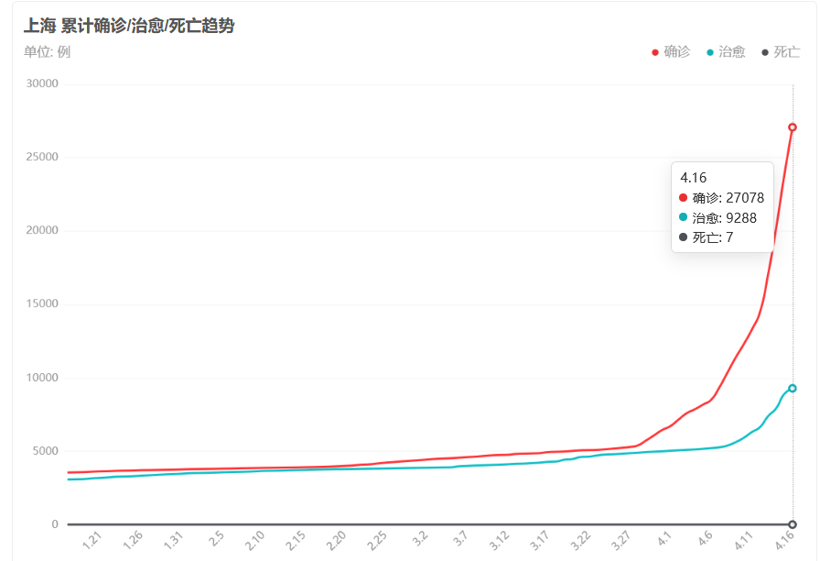

As the main epidemic area and the key gathering place of the automobile industry, the outbreak of the epidemic in Shanghai, Suzhou, Jilin and other places has an immediate impact on the automobile industry. At present, the number of confirmed cases in Shanghai remains high, which adds a lot of uncertainty to the resumption of work and production.

Big data report on epidemic situation in Shanghai, photo source: Baidu APP

How long will the impact of the epidemic on the car market last? Nearly 40% of the participants said it would be between 1 and 3 months, while another 30% said the impact would be between 3 months and half a year.

In response, the head of a local smart driving solution provider said, "due to delays in the delivery of products or services from upstream suppliers, this delay will also take some time to transmit from the supplier to OEM, and is expected to have a lasting impact on the automotive industry in the coming months."

The relevant person in charge of a joint venture car company also said that in view of the complexity of the automobile supply chain and the possibility of a recurrence of the epidemic, even if subsequent production resumes, some suppliers may not be able to supply the goods.

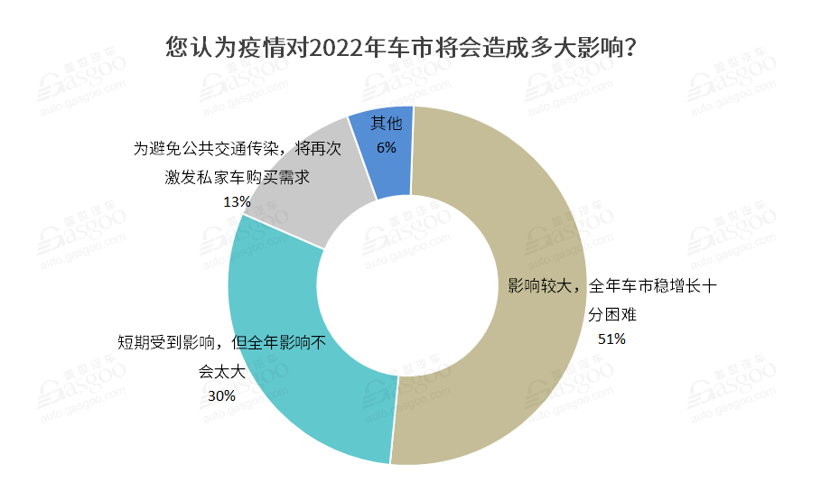

For the whole year of 2022, more than half of the participants believed that the epidemic had a great impact on the auto market for the whole year, and it was very difficult for the auto market to grow steadily throughout the year.

According to the statistics of the Federation of passengers, in March 2022, retail sales in China's passenger car market reached 1.579 million, down 10.5 percent from the same period last year, up 25.6 percent from January to March, down 4.5 percent from the same period last year and 230000 from the same period last year.

The Federation pointed out that from the overall market level, as the number of newly confirmed local cases is still on the rise in early April, employees of small and medium-sized enterprises are facing tremendous survival pressure, and retail sales in the domestic car market in April are expected to be much lower than those in March. If the epidemic continues in Shanghai and other places, it is expected to bring 20% of the production loss to the auto industry.

In response, senior analysts at the Gaishi Automotive Research Institute said that the automobile industry in areas with severe epidemics such as Shanghai and Changchun is well developed, bringing together a number of head car companies, such as SAIC, FAW-Volkswagen, Tesla, and so on. These two regions alone account for 20% of the annual domestic automobile output. At the same time, the R & D and manufacturing bases of the world's leading Tier-1 enterprises in these regions are densely distributed, and the production shutdown and logistics control caused by the epidemic will lead to great pressure on normal production, and will also lead to insufficient supply chain supply, thus affecting the normal production of the automobile industry in other places such as the Yangtze River Delta and the central region. The analyst also pointed out that as the overall market faces geopolitical conflicts, rising raw material costs and the triple impact of local outbreaks, the car market is expected to fall off a cliff in the second quarter of this year, which is a very dangerous signal for the whole year.

However, 30% of participants believe that the epidemic will have an impact on the short-term market, but the impact for the whole year will not be too great. The confidence of these participants stems from the fact that vehicle enterprises, supply chain enterprises, and even logistics and other supporting enterprises under the impact of the epidemic are actively responding. Although small project nodes will be delayed, people are still confident in promoting the overall progress of the project, and the pace of research and development and production are basically advancing steadily in accordance with SOP. In particular, the government has stepped in to guarantee supply, and it is believed that the problems and pressures faced by the industrial chain will be gradually resolved, and the worry of a large-scale suspension of production in the national automobile industry in May will no longer exist.