In August 2021, the Central sixth Ecological Environmental Protection Supervision Group inspected Daye Nonferrous Metals Group Holdings Co., Ltd. (hereinafter referred to as Daye Nonferrous Metals Company), which is a subsidiary of China Nonferrous Mining Group Co., Ltd. (hereinafter referred to as China Nonferrous Group). The main responsibility of Daye Nonferrous Company is not in place, the environmental pollution is serious and the risk is prominent.

I. basic situation

Located in Huangshi City, Hubei Province, Daye Nonferrous Co., Ltd. is a secondary enterprise of China Nonferrous Group, mainly engaged in copper mining, smelting and processing, with an annual production capacity of 300000 tons of anode copper, 600000 tons of cathode copper and 200000 tons of scrap copper. It has jurisdiction over 8 directly subordinate units, including smelter, Fengshan Copper Mine, Tongshankou Copper Mine and Chi Mashan Copper Mine, as well as subsidiaries of Shengxiang Copper, among which Chi Mashan Copper Mine stopped production in 2015.

II. Main problems

(1) serious environmental pollution

On-site inspection found that the waste copper waste treatment facilities in the smelter of Daye Nonferrous Co., Ltd. are virtually non-existent, the shaft furnace flue gas is discharged directly without collection and treatment, the anode furnace flue gas is unorganized and obvious, and the factory area is filled with smoke. The operation of the flue gas collection and treatment system of the smelting furnace in the anode copper smelting workshop is not normal, and the flue gas leaks a lot. Although the converter workshop built flue gas collection and treatment facilities, but because the factory building is old and can not be closed, the converter open production, the collection effect is very poor, and the unorganized emission of flue gas in the production process is very prominent. The equipment of the sewage acid treatment workshop was seriously corroded, and a large amount of heavy metal sludge and waste water leaked into the Rain Water pipe network. According to the sampling and monitoring of Rain Water in the waste acid workshop, it was found that the concentrations of arsenic, lead and cadmium were 17.3mg / L, 9.92mg / L and 0.912 mg / L respectively, exceeding the emission limit of Copper, Nickel and Cobalt Industrial Pollutant Emission Standard by 33.6,18.84,8.12 times. Online monitoring data show that since 2019, the average hourly concentration of sulfur dioxide in sulphuric acid tail gas from smelters has exceeded the emission limit of Copper, Nickel and Cobalt Industrial Pollutant Emission Standard for 2161 times. Since 2018, Daye Nonferrous has been punished 12 cases by local authorities for environmental violations, with a penalty amount of 8.776 million yuan.

Fig. 1 abnormal operation of flue gas collection and treatment system of smelting furnace in anode copper smelting workshop, and a large number of flue gas leakage

Fig. 2 the problem of unorganized emission of converter flue gas in Daye Nonferrous Co., Ltd is still serious.

(2) the hidden dangers are prominent.

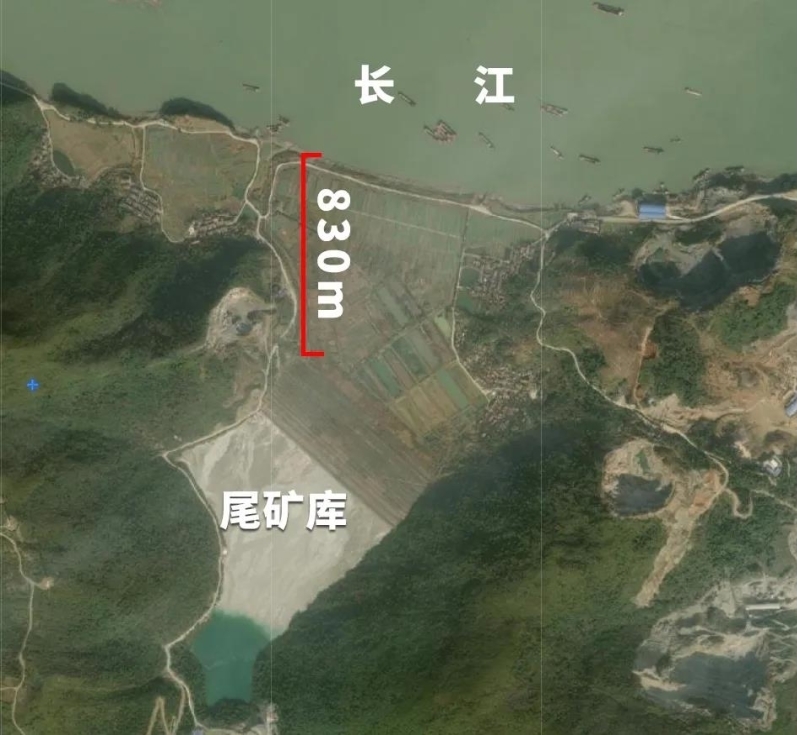

The tailings reservoir of Fengshan Copper Mine of Daye Nonferrous Co., Ltd. is more than 800 meters away from the main stream of the Yangtze River. In 2012, the environmental impact assessment of the tailings reservoir expansion required the construction of 2550 meters of flood intercepting ditches. In 2019, the Hubei Provincial tailing Reservoir pollution Prevention and Control work Plan (2019-2020) issued by the Hubei Provincial Department of Ecological Environment also clearly requires it to improve the interception and drainage system and reduce the amount of Rain Water entering the reservoir. However, the enterprise has not built a flood intercepting ditch, resulting in a large amount of Rain Water mixed tailings wastewater discharged directly into the river, with a discharge capacity of 2.79 million cubic meters in 2020. The actual displacement per unit product is 3.48 cubic meters per ton, which is 3.48 times of the benchmark discharge limit per unit product stipulated in the discharge Standard for Industrial pollutants of Copper, Nickel and Cobalt.

Fig. 3 the environmental hidden danger of the tailings reservoir of Fengshan Copper Mine of Daye Nonferrous Co., Ltd., which is more than 800 meters away from the main stream of the Yangtze River.

The notice of the relevant state departments on issuing the work plan to prevent and resolve the safety risks of the tailing reservoir requires that the tailing reservoir which has been out of use for more than 3 years must be closed within one year, but the Chi Mashan Copper Mine of Daye Nonferrous Nonferrous Company has stopped production since 2015. The tailing reservoir has been out of use and has not completed the closed treatment as required. By the time the inspector arrived, neither the closure of the storehouse nor the ecological restoration had begun. After the inspection of China Nonferrous Group in 2019 and pointed out this problem, Daye Nonferrous Company did not actively rectify the problem, and the management of the mining area was still chaotic, and even connived at other enterprises to illegally carry out mineral processing production by using the original dressing plant of Chi Mashan Copper Mine. mineral processing tailings are randomly stacked in the upper reaches of the tailings reservoir, and some tailings and mineral processing wastewater are discharged into the downstream Gongnong reservoir. The content of lead and arsenic in tailings is 4246 mg / kg and 140mg / kg respectively, which poses a serious threat to downstream reservoirs and villages.

Fig. 4 A large number of tailings are piled up at random in the upper reaches of the tailings ditch of Chi Mashan Copper Mine of Daye Nonferrous Co. the content of lead and arsenic in the tailings is 4246 mg / kg and 140mg / kg respectively.

(3) perfunctory to deal with rectification and reform

Since 2017, the local government and relevant departments have conducted seven interviews or sent letters to urge Daye Nonferrous Co., Ltd. to rectify the outstanding eco-environmental problems, but the company has dealt with them perfunctorily. During the first round of central eco-environmental protection inspectors in 2016, people reported that the smelter of Daye Nonferrous Company had serious pollution. The relevant local departments investigated and ordered Daye Nonferrous Co., Ltd. to formulate a rectification plan and make rectification within a time limit. According to the rectification and reform plan made by Daye Nonferrous Co., Ltd., the standard upgrading of smelter sewage treatment facilities should be completed by the end of 2018. However, the actual work avoids the important points and neglects the light, and makes negative rectification. The inspector found that the smelter adopted the emergency measures of adding iron powder and hydrogen peroxide to the sedimentation tank to carry out "rectification", but did not solve the fundamental problems such as non-standard construction of facilities, old and damaged rain and sewage pipe networks, and even used ditches without anti-seepage measures as aeration tanks. On-line monitoring data show that the discharge of wastewater still exceeds the standard in some periods, in which the highest concentration of cadmium is 0.089 mg / L, which exceeds the discharge limit of pollutants from urban sewage treatment plants by 7.9 times.

Third, cause analysis

Daye Nonferrous Co., Ltd. has a negative attitude towards the long-standing problems of environmental pollution and hidden risks, perfunctory response to the demands of the masses and regulatory requirements, weak implementation of the responsibility of the main body of ecological environment protection, and the problem of inaction is prominent. China Nonferrous Group is not in place to supervise and inspect many eco-environmental problems existing in Daye Nonferrous Co., Ltd., the supervision and rectification is not effective, the assessment is not strict, and the management responsibility of the group is not fulfilled effectively.

The inspection team will further investigate and verify the relevant situation and do a good job in the follow-up supervision work as required.