SMM Network News: at present, in the face of the production pressure caused by the lack of resources, environmental pollution and safety accidents, a global mining digital transformation revolution is accelerating. According to statistics, there are nearly 20,000 metal mines above the scale in China, of which underground mining accounts for 70 percent, of which only about 10 percent are large-scale mines with a high degree of modernization and the level of technical equipment and comprehensive utilization of resources close to those of developed mining countries. the equipment of other large-scale mines and small and medium-sized mines is still at the level of the 1980s and 1990s. The comprehensive utilization rate of resources is low, the management mode is extensive, and the safety and environmental problems are prominent. On the road of ensuring the sustainable supply of mineral resources, promoting energy saving and emission reduction, and promoting the modernization of the mining industry, how to take technology as the driving force of innovation to lead China's transformation from a "big mining country" to a "mining power"?

With the continuous promotion of the transformation of new and old kinetic energy and the reform of supply-side structure, information and communication technology is changing with each passing day, and social development has entered a new era of intelligent development. In recent years, under the guidance of a series of major strategies and actions, such as "Network Power" strategy, national information development strategy, big data strategy, "Internet +" action plan, "5G + Industrial Internet" 512 project promotion plan, the intelligent construction in China's mining field has been continuously deepened, and the technical requirements for high-tech and high-quality development of the industry have been continuously improved.

As the leader of China's intelligent mines and the solution provider of intelligent manufacturing system of the Ministry of Industry and Information Technology in 2020, Enfei of China relies on 67 years of rich experience in engineering implementation and profound technical accumulation. Academicians of the Chinese Academy of Engineering, more than 100 doctoral research teams and multi-professional engineers and technicians jointly carry out special research. The Beijing Engineering Research Center of China Mining Informatization Collaborative Innovation Center was jointly established with the National Supercomputing Tianjin Center, realizing the deep integration of a new generation of information technology and industrial control technology, and launching the digital integration solution of intelligent mine MIM+, which has become the "key of Enfei" to promote the digital and intelligent transformation of the industry.

Who is in the MIM+ family?

China Enfei's intelligent mine MIM+ digital integration solution consists of three main parts: full information visualization (MIM Transparent), full process digital (MIM Digital), operation cycle digital twin (MIM Twins).

Full-information visualization (MIM Transparent) can digitize the top-level design of the project, make the project construction and implementation units coordinate their work according to unified standards, and cover the full life cycle data flow in the two stages of project construction and operation and maintenance. Carry on the full information display of the three-dimensional model, equipment and materials, data information, survey, design and construction management during the construction period, and the full information visual display of the real-time production control data, operation and maintenance data and enterprise management data during the operation and maintenance period.

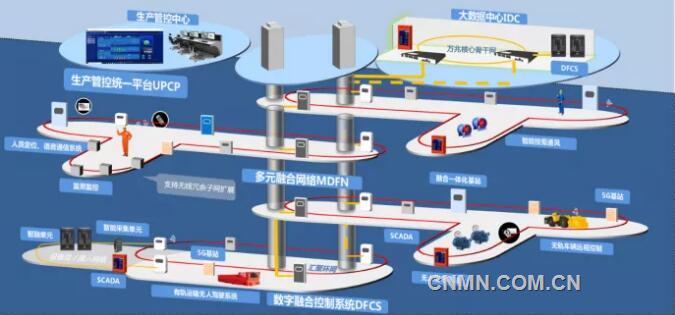

The whole process digital (MIM Digital) condenses the digital fusion technology DFCT (Digital Fusion Communication Technology), of Enfei intelligent mine in China, which is composed of "one system, one network and one platform".

The "one system" digital fusion control system DFCS:DFCS can realize the production monitoring, all-factor data acquisition and edge intelligent control of the whole production process of the mine through intelligent fusion control unit and edge computing terminal, multi-data intelligent acquisition unit, multi-data fusion and integrated base station.

"one network" multi-data fusion network MDFN:MDFN adopts industrial Internet data security penetration data stable transmission technology, through a unified edge cloud cooperation industrial Internet solution, to establish a flexible, scalable, low-cost multi-level, hierarchical, integrated network in the mining area. Take the multi-fusion network constructed by the integrated fusion technology as the core, cover the whole mine production and business process, and build the whole mine production information superhighway, effectively simplify the network structure, improve the degree of digital fusion, reduce infrastructure investment and reduce operation and maintenance costs.

Through the visualization of production management and control, intelligent information processing and the integration of collaborative operation, "one platform" unified production management and control platform UPCP:UPCP realizes the fields of monitoring, control, scheduling, management, operation and maintenance, operation and maintenance, and integrates the systems of stope, equipment, personnel, energy, safety and environment on the same platform for collaborative management and control, which greatly improves the efficiency and efficiency of mine operation management and control.

The whole process Digital (MIM Digital) of Enfei Intelligent Mine in China

Business cycle Digital Twin (MIM Twins) combines nearly 70 years of engineering design, engineering data and project practical experience of Enfei in China, and carries 3D modeling technology, system simulation technology, engineering simulation technology, virtualization technology, big data service technology, cloud computing technology, expert system technology, artificial intelligence technology, etc., to establish real-time data coupling and interactive interface between virtual system and physical system. The realization of Synchronize mapping and interconnection between virtual system and physical objects can effectively provide intelligent and visual assistant decision-making for mine production operation and process site, such as scheme evaluation, dynamic optimization, emergency disposal and so on.

How effective is the MIM+ family?

MIM+ digital integration solution can realize all-element modeling of mine, and can establish the diversified corresponding relationship between physical entity data platform and digital virtual model based on material flow, energy flow, information flow, value flow and business flow, and realize the whole process of data collection, digital transmission, knowledge mining, information feedback and so on. The whole process of raw material purchasing, logistics and transportation, warehousing management, production process to market forecast and product sales, the overall digital fusion of all elements of "human, machine, material, law and ring", and multi-level digital collaborative computing, such as edge computing, cloud computing, intelligent management and terminal application, provide enterprises with an integrated digital solution for intelligent collaborative management and control based on the industry knowledge base (MIM Knowledge).

More importantly, the all-factor data platform also encapsulates countries, industry standards, industrial knowledge, mathematical models and management models. On this basis, management applications such as "process butler", "equipment butler", "energy butler", "environmental butler" and "safety butler" are developed to realize the intelligent solution of enterprise "butler integration". Open up the whole life cycle service process of digital design delivery-digital construction management-digital production operation and maintenance, break through the core technology of intelligent manufacturing, change the ecological chain mode and operation management mode of non-ferrous industry, provide enterprises with information and intelligent comprehensive digital overall solution, so as to greatly improve the operation efficiency of enterprises and improve the intelligent construction level of intrinsically safe metal mines. We will promote the digital transformation and intelligent upgrading of traditional industries, and improve production quality and economic benefits.

How awesome is the industry classic created by MIM+?

At present, China Enfei has provided digital, intelligent top-level design and digital integration solutions in many foreign mines. Among them, the intelligent mine general contracting project of Sifei Qianbi Copper Mine has become the "national big data industrial development pilot demonstration project in 2020" by virtue of its leadership and benchmarking, and has attracted much attention from the industry.

Qianbixi Copper Mine is the first non-ferrous metal mine in China to operate successfully overseas, which is known as "a landmark project of China-Africa cooperation". Since China Nonferrous Mining Group took over Qianbixi Copper Mine in 1998, it has long-term and close cooperation with Enfei in mining, dressing, smelting and other projects, creating a banner of "going out" in China's non-ferrous industry. To meet the needs of digital transformation and intelligent upgrading of the mining industry, China Nonferrous Mining Group commissioned China Enfei to implement the "Mine Informatization Automation Fusion Control system" project. China Enfei conducted in-depth research and analysis on the underground mining of Qianbixi Copper Mine from the perspective of industry digital transformation, and made clear the key to the intelligent upgrade of production system, transportation system and production auxiliary system-digital fusion control.

The intelligent mine digital fusion technology DFCT is applied in the main west orebody for the first time. Focusing on the intelligent management and control of power supply and distribution, the whole mine network is designed by using the framework of fusion network, fully considering the three demand aspects of mining production system, mine transportation system and production auxiliary system, iterative innovation and fusion innovation from three aspects of technology, management and concept. Through the renewal and transformation of the automation and information system and the application of the intelligent automatic mining and transportation system, the process control and data collection of all production factors from the monitoring end of the field layer to the enterprise management are realized, and the problem of isolated island of mine monitoring information is solved. at the same time, its open architecture design provides the function of integrating customer business level information and numbers, and integrates multiple subsystems to form a large mine production management and control system. The mine production efficiency and system maintenance efficiency are effectively improved, the digital control and service platform of the whole production process is established, and the coordination between systems is improved.

Qianbixi main West Orebody is equipped with "Digital engine" Qianbixi main West Automation and Electric Energy Management and Control Project mainly upgrades the electric energy management and control system, underground drainage system, underground mud drainage system, fixed equipment on-line monitoring, video surveillance system, drainage pumping station fire alarm, production scheduling and information management system of the main west orebody, so as to create a full-process digital (MIM Digital),. Through digital fusion control system DFCS and multiple data fusion network MDFN, to comprehensively improve the level of control and information management, the construction of a mine production management and control unified platform UPCP, to reduce production costs. Since 2017, the project has implemented the upgrading of digital, information and automation technology. at present, it has realized personnel positioning system, communication network covering the whole mine, large-scale and intelligent mining operation equipment, and auxiliary production system. such as drainage system to achieve automation unattended, production management system to achieve information, reduced operators diverted to the southeast orebody. At present, the per capita production and labor efficiency has increased from 2 tons per person / day in the past to nearly 4.81 tons / person / day, the labor productivity has increased by 1.8 times, the comprehensive total cost of per ton of copper has been reduced by 13.4% compared with that before the transformation, and a number of equipment shift indicators have set a new record in Zambia. the main indicators have reached the advanced level of similar mines in Africa.

The southeast orebody of Qianbixi becomes a "super version of digital mine". The southeast orebody project of Qianbixi Copper Mine has a total investment of US $830 million and a designed mining scale of 10000 tons per day, which is the largest investment project by China in Africa. China Enfei, as the general contractor of its automatic information fusion system, carries out a new fusion control design and integrated application of underground digital and automatic mining, builds a MIM+ digital integrated intelligent mine, deeply integrates information technology and mining technology, and enables the respective production control systems of mines to realize system fusion control (DFCS), network fusion (MDFN) and data fusion (UPCP),. On-site production of all systems to achieve real-time monitoring, the main system to achieve remote operation and automatic operation.

The automation and digitization of working layer equipment and technology of southeast orebody has been fully implemented, and the project adopts advanced mine digital modeling software to realize the comprehensive digital operation of geological modeling, mining design, medium-deep hole design, survey acceptance and planning. Three-dimensional display of mining design, geology, mining, survey and planning have entered the "highway". Intelligent equipment is used in shaft driving and support, and the related process production realizes intelligent and digital operation in an all-round way. The stope transports ore through automatic scrapers and unmanned trucks, and automates mining operations through Automine and Optimine systems. the practical application shows that the running speed of scrapers is increased by more than 20%. In the underground, the fusion control network of the main production areas is fully covered, in which transportation, lifting, water supply, power supply, drainage, ventilation and other production auxiliary systems realize automatic control and intelligent operation. In the surface production management and control center, the production data of the whole mine are analyzed, managed and dispatched by the unified platform of production management and control, which lays a foundation for the subsequent establishment of the whole mine big data service platform and operation digital twin (MIM Twins), three-dimensional platform and information visualization (MIM Transparent) platform.

It is the vision of the "digital benchmark" mine of Qianbixi Copper Mine to achieve safe and efficient production by benchmarking to the best mine in the world with high digitization, high production efficiency and low production cost. it is also the long-cherished wish of Enfei to promote the digital transformation of the traditional mining industry in China.

Carry forward the past and forge ahead into the future. China Enfei will continue to promote technological upgrading and platform building, improve the production efficiency, decision-making ability and management level of enterprises, strive to build a digital transformation of the industry, new business type, and enhance the international competitiveness of "non-ferrous + digital". Assume the national responsibility of high-quality development to promote the transformation from a big mining country to a mining power.

"Click to sign up: 2020 Fifth China Electrotechnical Materials supply and demand Trade Summit

Contact: Xu Dean 18512069994

Scan the code to participate in the meeting or apply to join the SMM Electrical Industry Exchange Group