SHANGHAI, Apr 3 (SMM) – Chinese silicon plants may face difficulties to resume production as scheduled in the wet season starting from June as the global widespread COVID-19 has disrupted the supply chain and led to a shortage of raw material wood charcoal. SMM learned that most silicon plants have conducted maintenance and tried to secure feedstock for the preparation of resumption.

Mass application of wood charcoal in domestic silicon production is mostly seen in Yunnan province, where silicon mills use wood charcoal as a reducing agent to ensure the quality of finished products. Besides providing a carbon source for smelting, wood charcoal can also increase production due to its favourable properties.

While Myanmar is the major source of wood charcoal supply in Yunnan, the Yunnan Customs has suspended import from the country due to the fast-spreading of COVID-19. This kept silicon producers in Yunnan depleting their inventories of wood charcoal.

As of this week, silicon plants in operation in Yunnan are mostly located in Baoshan and Nujiang areas and stocks of wood charcoal are insufficient. Some producers have only around one month of feedstock to meet production, and stockpiles of Chinese traders are limited. Large-scale companies face even severe shortage of wood charcoal.

In addition, reduced production of wood charcoal near the China-Myanmar border drove traders to secure products from alternative sources. This added to the transportation costs and eroded profits, pushing some market participants out of the market and intensifying the supply tightness.

Supply of silica in Yunnan has also tightened up due to import disruption from Myanmar and Vietnam caused by the COVID-19. Production at domestic mines, another source of the raw material for Yunnan, came lower than the previous year as the pandemic delayed the resumption of mining operations and the return of workers. The silica mining will again halt in the upcoming rainy season and this reinforces concerns about supply shortage.

The resumption of silicon production in Dehong of Yunnan will likely be later than as compared to previous years as local plants are required to install desulphurisation equipment. Production could only restart after the installation is checked and accepted by authorities, which should be done before June 30. The installation has kicked off in most silicon mills in Yunnan.

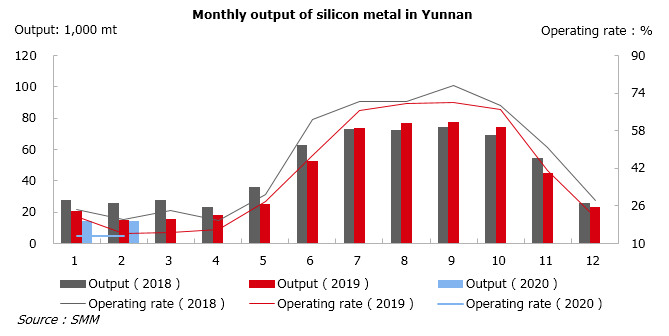

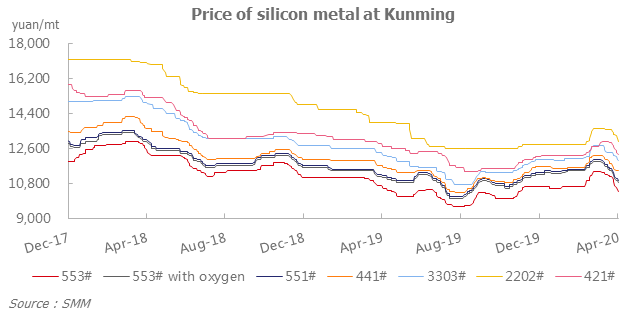

The anticipation of higher supply in the wet season had kept the market bearish about silicon prices, which partly accounted for the recent steep declines in prices. However, SMM expects the raw material shortage, limited profits at silicon mills and desulphurisation issue to slow down the rebound of silicon supply in the wet season. The operating rates at silicon producers then will likely stand lower than the previous year.

![This Week, Platinum and Palladium Experienced Significant Pullbacks, End-Use Demand Recovered, and Spot Market Trading Was Normal [SMM Platinum and Palladium Weekly Review]](https://imgqn.smm.cn/usercenter/obeMy20251217171735.jpg)

![Silver Prices Continue to Pull Back, Suppliers Remain Reluctant to Sell, Spot Market Premiums Hard to Decline [SMM Daily Review]](https://imgqn.smm.cn/usercenter/LVqfJ20251217171736.jpg)